Grove GMK7450 all-terrain crane assembles Potain tower crane for roof replacement at Italian tomato processing plant

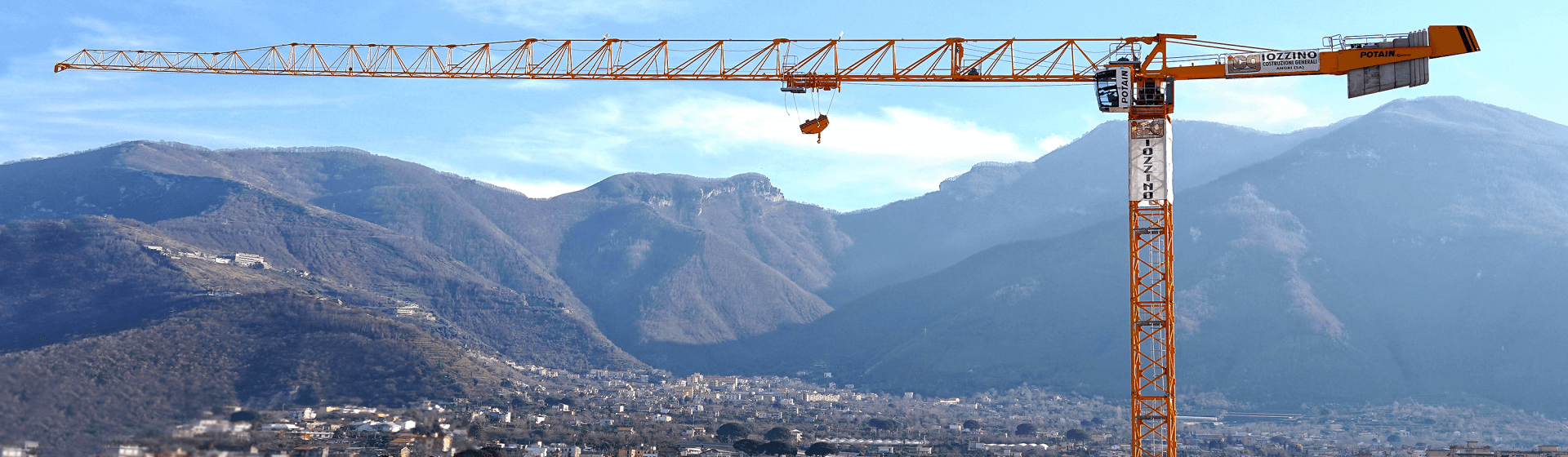

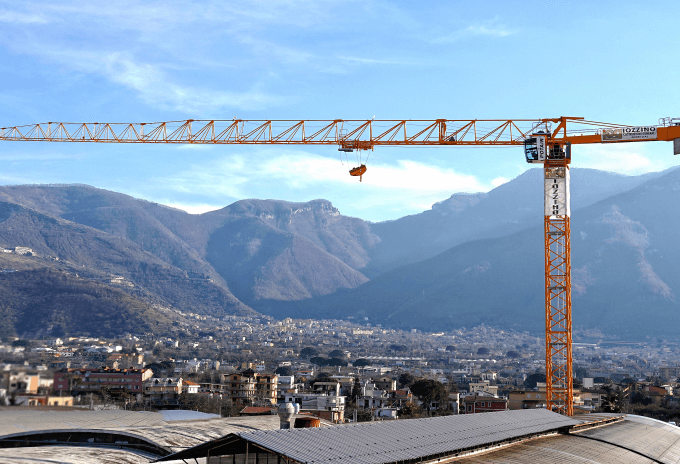

- Showcasing the strength and breadth of Manitowoc's capabilities, a Grove GMK7450 all-terrain crane has assembled a Potain MDT 219 tower crane in the middle of the La Doria plant in Salerno, Italy.

- Contractor Iozzino Costruzioni Generali purchased the MDT 219 from Italian Manitowoc dealer EDILCOM GRU to carry out the lifting operations required for the rebuild of the factory roof.

- The powerful GMK7450 with MegaWingLift erected the MDT 219 with ease from a distance of 85 m.

In Salerno, Italy, Iozzino Costruzioni Generali has been contracted to carry out the lifting operations for the rebuild of canned tomato and legume producer La Doria’s factory roof. The Salerno-based contractor/builder has been a specialist in the consolidation, restructuring and restoration of private and civil works since 1997 — and purchased a Potain MDT 219 top-slewing tower crane especially for the job. The MDT 219 joins several other Potain cranes in the Iozzino Costruzioni Generali fleet including Hup 40-30 and Igo 36 self-erecting cranes, and two MC 85 city cranes.

The 25,000 m2 roof at the La Doria factory is structurally complex and operations will continue throughout the construction work. The MDT 219 will lift the reinforcement for the pre-existing columns and position pairs of arches connected by purlins. Once this is complete, the existing vaults will be removed, and the new roof built on top.

“The customer required a reliable brand for this complex rebuild process because as the factory continues to operate it doesn’t allow for any stops. The Potain MDT 219 was also the perfect crane in terms of dimensions and capacity,” explained Luigi Russo, director at dealer EDILCOM GRU srl, which supplied the crane.

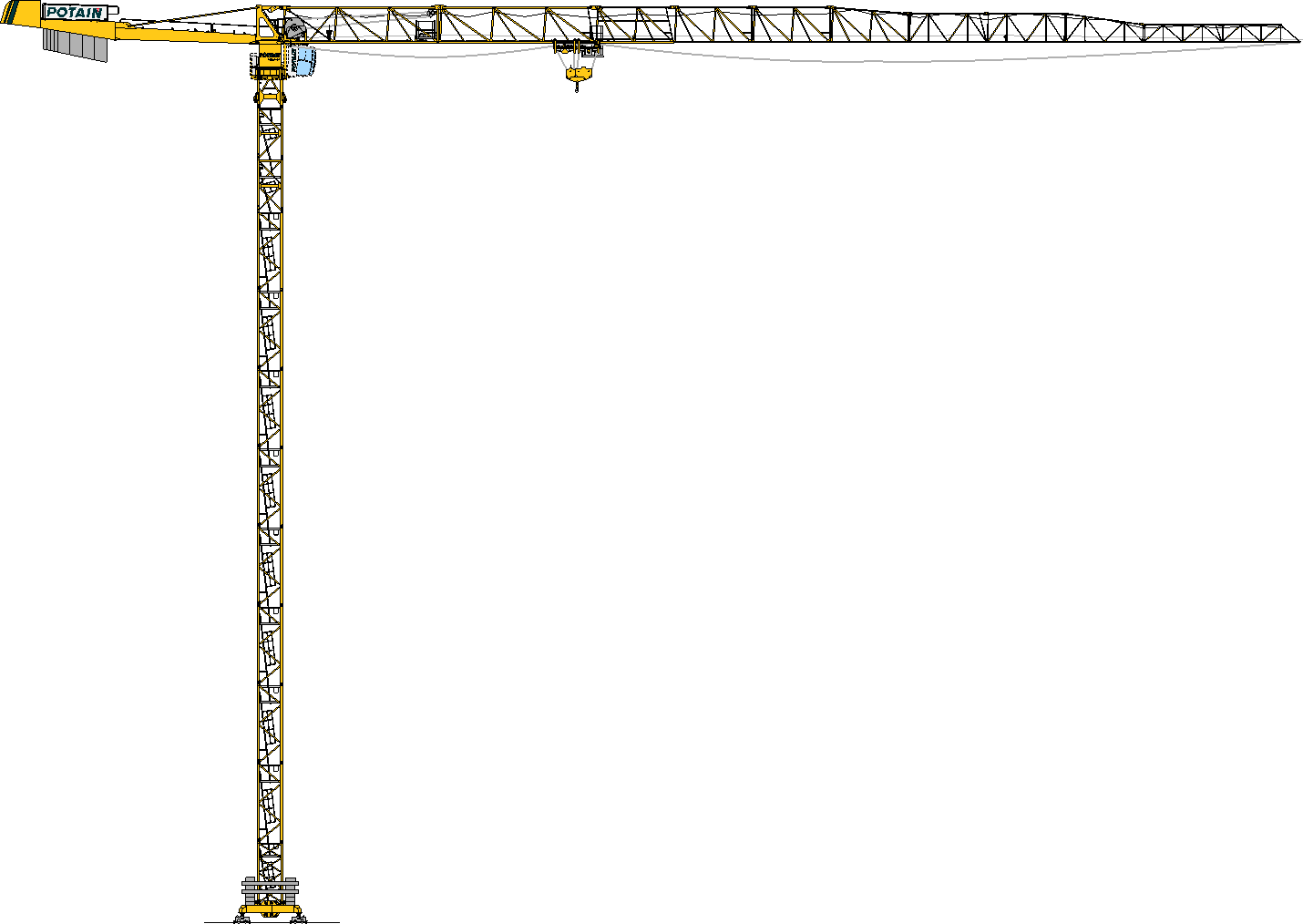

The MDT 219 is a 10 t maximum load crane, which has a maximum free-standing height under hook of 66.8 m (C25), a 65 m maximum jib length and is able to lift 1.9 t at 65 m radius. Iozzino Costruzioni Generali chose to have an Ultra-View cabin and a 50LVF25 hoisting winch. The crane is also equipped with CCS (Crane Control System), which provides fast set-up and increased productivity on site. The contractor also opted to have the CraneSTAR Diag asset management system to carry out diagnostics remotely and plan maintenance and lifting schedules to maximize efficiency and uptime.

The perfect partner

As well as supplying the MDT 219, Manitowoc dealer of more than 20 years EDILCOM GRU srl organized the crane’s erection at the La Doria factory using a Grove GMK7450 all-terrain crane, owned by Palumbo Group Piazzale Pisacane from Napoli. The assembly and the crane erection process took just five days.

“The MDT 219 is simple, fast and efficient to erect, which has saved Iozzino Costruzioni Generali time and money. The crane sections are compact and folded for easy transport to the job site, while the easy pinning and multiple slinging points provided greater control when assembling and lifting the jib. The jib and counter jib were unfolded and assembled on the ground,” Luigi Russo said.

Still, the MDT 219 requires a reliable and capable partner to erect it. This was especially important to Iozzino Costruzioni Generali given the planned position of the tower crane directly in the middle of the factory’s roof. The Grove GMK7450 offered the reach and capacity required to assemble the MDT 219 from 85 m away. The seven-axle 450 t capacity all-terrain crane provides an exceptional strength-to-weight ratio thanks to the unique MEGAFORM boom design, while the large wear pads ensure optimum boom alignment and effective transition of weight between sections when lifting. These features enable greater lifting capacities at any radius, as does the fully hydraulic TWIN-LOCK boom pinning system. TWIN-LOCK uses two pins horizontally mounted on a single telescopic cylinder that moves a boom section into position, reducing weight that is used to strengthen the crane elsewhere.

Lifting capacity is further enhanced by the optional MegaWingLift, which provides rigidity when working with long boom/jib/counterweight combinations, increasing the load chart by up to 50% on the main boom and close to 100% on the luffing jib.

“The cranes satisfied all the customers’ expectations,” Russo said. “The GMK7450 lifted the 5.9 t, counter jib, 7.49 t towerhead and cabin, and 10.7 t equipped jib all at a distance of 80 m from the place where the MDT 219 had been erected at 50 m height, which ensured efficiency on site.”

The MDT 219 will work on site for three years before the GMK7450 returns to dismantle it.

CONTACT

Cristelle Lacourt

Marketing Communication Manager | Tower Cranes Europe & Africa

Manitowoc

T +33 472 182 018

cristelle.lacourt@manitowoc.com

Insa Heim

Marketing Communication Manager | Mobile Cranes Europe & Africa

Manitowoc

T +49 4421 294 4170

insa.heim@manitowoc.com

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image