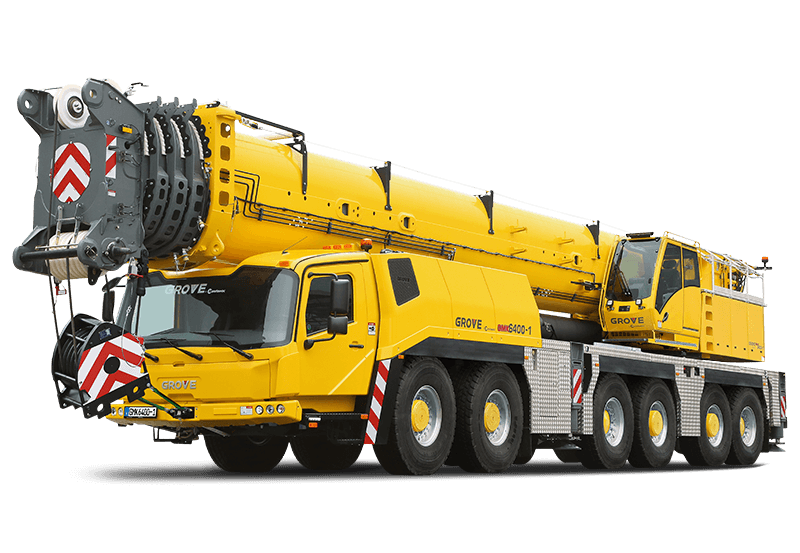

First Grove GMK6400-1 in North America goes to Heaton Erecting in Georgia

- The largest model in Grove’s six-axle all-terrain range was delivered to Heaton Erecting in Atlanta.

- The crane features a MegaWingLift™ attachment, luffing jib, and MAXbase outrigger system, enabling it to take on jobs typically reserved for seven- or eight-axle cranes.

- The GMK6400-1 was Heaton’s latest crane to be supplied by Ring Power Crane; the two companies have worked closely together since 2009.

Heaton Erecting, a provider of professional crane, rigging, and transportation services to the Atlanta, Georgia, construction market, has taken delivery of North America’s first Grove GMK6400-1.

The new flagship six-axle, 450 USt (400 t) all-terrain crane, which was supplied by Manitowoc dealer Ring Power Crane, expands Heaton’s growing fleet of Grove cranes at an opportune moment, with business booming as Atlanta continues to live up to its reputation of being one of the country’s fastest-growing cities.

“A lot of the work we do is building data centers, and the GMK6400-1 will be a great fit with that type of mechanical work,” said Billy Hancock Jr, vice president at Heaton Erecting. “We’ll be installing 72 cooling units on the roof of one data center soon, as well as providing a hook for pipes, lights, and other components. This crane will also give us the ability to assist in the assembly and disassembly of tower cranes across Atlanta.”

The crane outperforms the competition in every category, boasting a maximum tip height of 448 ft (136.6 m) from within a smaller overall footprint — at 57.5 ft (17.5 m) in length, 9.8 ft (3 m) minimum width and a boom overhang of 5.9 ft (1.8 m). This makes it an ideal fit for bridge construction, wind farm work, and other energy and infrastructure applications.

Heaton ordered the crane with the optional, self-rigging MegaWingLift™ attachment, which can increase lift capacity on the 197 ft (60 m) five-section main boom by up to 70% — from 84,000 lb (38 t) to 141,000 ft (64 t) at 40 ft (11 m) working radius, for example.

The MegaWingLift™ attachment will also boost the lift capacity of the 82 – 259.2 ft (25 – 79 m) luffing jib by up to 400%, perfectly positioning Heaton to take on jobs that would usually require a much larger crane. And, as the successor to the GMK6400, the new model makes such tasks even easier through the addition of Manitowoc’s Crane Control System (CCS).

“With the MegaWingLift™, the luffing jib, and the combinations that we’ll be using the most, the GMK 6400-1 will give us a huge competitive advantage,” Hancock said. “Just look at how great its load chart is, even compared with seven-axle cranes!”

“Another reason why it’s such a good fit for us is the Crane Control System. We have a large GMK fleet, so our operators and mechanics are very knowledgeable in using CCS for optimum results. So, whenever manpower is low, we can reposition operators and they’re immediately comfortable with it. We’re also expecting to reduce our assembly time even further so that we’re quickly in and out of the jobsite.”

One tool to enable this desired speedy setup is the MAXbase variable outrigger positioning system, which enables outriggers to be extended in a variety of symmetric or asymmetric lengths when obstacles prevent their full extension. The system works in conjunction with Boom Configurator mode to achieve longer working radii and higher main boom capacities in less-than-ideal environments.

Easy rider

Heaton’s mobile crane fleet includes GMK5250L, GMK5240, and GMK5150L all-terrains as well as TMS9000E and TMS800 truck cranes, and two National Crane NBT60XL and three NBT45 boom trucks.

“Over the years, we’ve transitioned to become more of a taxi fleet relying on our all-terrain cranes, and now that every job seems to require more and more capacity it’s always best to have the largest-possible roadable crane,” Hancock added. “We can legally drive this with the boom trailing behind in a three-axle dolly, but without the need for another crane assisting assembly on the jobsite.”

The crane is a smooth drive in transport mode, featuring a 577 hp (430 kW) Tier 4 Final/Stage V Mercedes-Benz OM473LA engine, 12-speed ZF transmission and MEGATRAK® suspension with automatic leveling system. At the jobsite, the MegaDrive™ 12x8x12 hybrid driveline, with axles 4 and 5 being driven hydrostatically, assumes control to optimize the ease of precise positioning.

The delivery of the GMK6400-1 was timed with on-site training provided by Manitowoc engineers to Heaton Erecting and Ring Power. One of the most trusted full-service crane dealers in the Southeast, Ring Power started its relationship with Heaton in 2009 and the two companies have since forged a close relationship.

“We are very excited about the impact the new GroveGMK6400-1 will make in our territory,” said Andrew Kurz, vice president of sales – utility, crane, and truck divisions at Ring Power. “Our team is extremely fortunate and proud to partner with Heaton and Manitowoc to bring this impressive crane to our market.”

Hancock echoed Ring Power’s sentiment. “Being able to build such strong relationships with our partners and customers is what keeps us in our unique position after 56 years in the industry,” Hancock concluded. “I've always been very impressed with Ring Power, especially their support on the service side.

“They recently sold us our GMK5250L, which we bought to take some of the workload off our GMK5240. It didn’t though — it just brought in more work, which was great! So, we’re extremely excited to see what our newest Grove has to offer.”

The GMK6400-1 is available for order worldwide.

CONTACT

Amy Crouse

Manitowoc

T +1 717 593 5960

amy.crouse@manitowoc.com