World’s first Potain MRH 175 hydraulic luffing jib crane commissioned for Glasgow apartment construction project

- On June 16, Irish Potain dealer Irlequip installed the world’s first Potain MRH 175 topless crane with hydraulic luffing jib technology on a job site.

- The crane will be used to construct a block of flats in Glasgow, Scotland, where the 10 m out of service radius and ease of erection makes it ideal for the confined location.

- Irish contractor MR Concrete placed an order for the new crane at Bauma 2019, where the new luffing jib technology was launched.

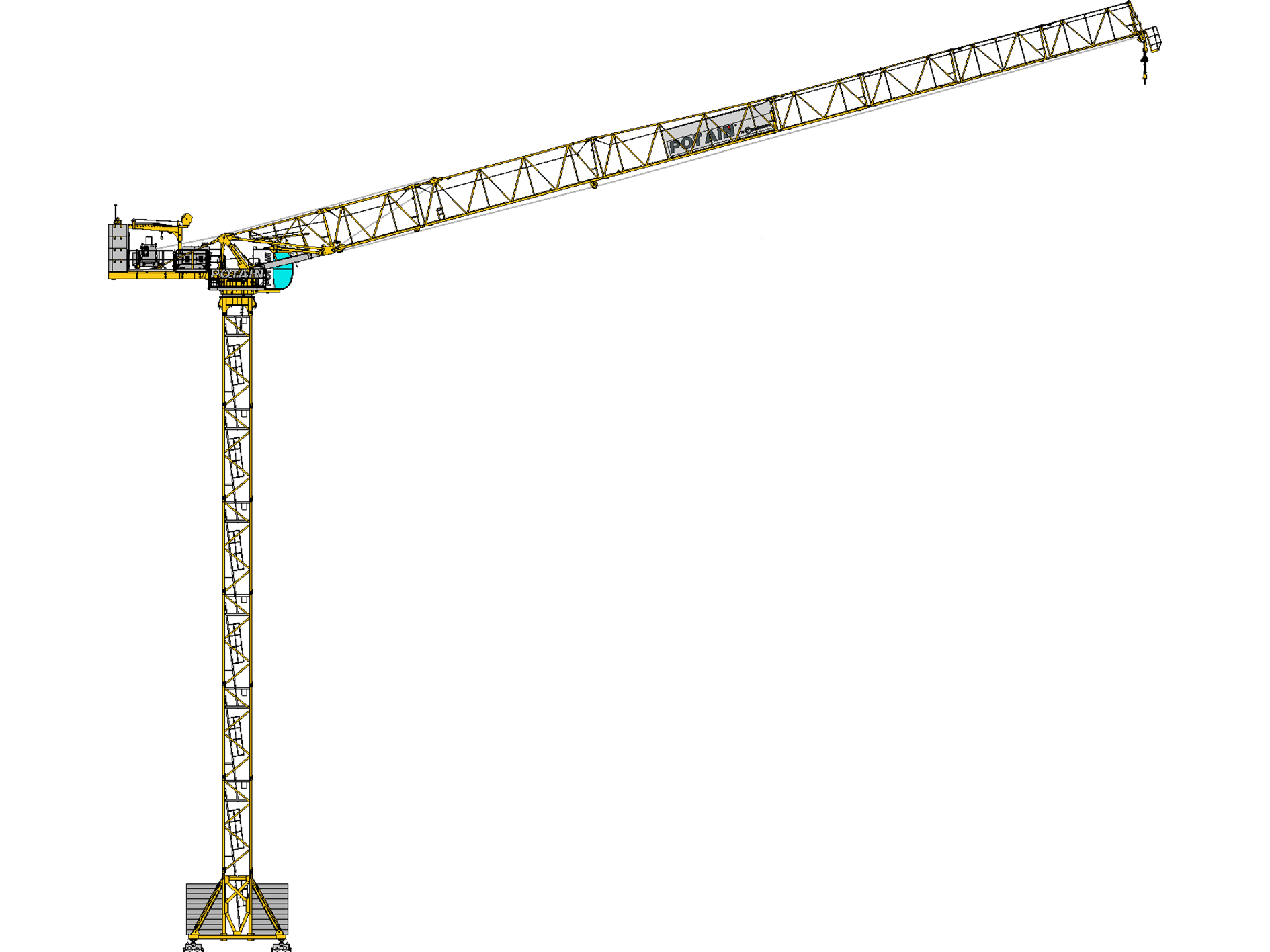

Reinforced concrete sub- and superstructure specialist MR Concrete has commissioned the world’s first Potain MRH 175 on a job site. With a maximum capacity of 10 t, the MRH 175 is the largest of a new generation of hydraulic luffing jib cranes launched at Bauma 2019.

MR Concrete purchased the Potain MRH 175 through Irish dealer Irlequip, based in Moate, Co. Westmeath, who will service it with support from Manitowoc UK. MR Concrete has been an Irlequip customer for over 16 years.

“We appreciate the opportunity to launch the MRH 175 and must acknowledge the confidence MR Concrete placed in us when awarding the order in Munich last year,” said John Ledwith, managing director of Irlequip. “Mutual trust, good support and fair play are what our relationship with MR Concrete is all about.”

The best of both worlds

The MRH range combines the advantages of an MR luffing jib with an MDT topless model, making the cranes straightforward to assemble on urban, high-rise construction or other job sites where space is limited.

They have a shorter counter-jib and out-of-service radius than rope-luffing alternatives, which also frees up valuable space on job sites. The MRH 175 delivers an out-of-service radius of just 10 m, regardless of jib length.

“MR Concrete needed a hydraulic luffer to allow it to operate in tight and congested sites with a minimum out of service radius, which made the MRH 175 an ideal choice,” Ledwith said.

Luffing the crane from horizontal to vertical is efficient, taking less than two minutes, delivering optimum productivity on the job site. The maximum line speed is 215 m per minute when working with the high-performance 75HPL25 hoist.

In addition, the MRH 175 is compact to transport, needing only four standard containers. The elements weigh under 7.7 t and there is a single jib/jib foot package.

MR Concrete’s first job for the MRH 175 is lifting the concrete frame, cores, floors, columns and stairs for an 18-story block of 324 flats at Buchanan Wharf in Glasgow, Scotland.

Speedy erection and operation

The crane was installed on June 16, with a 35 m jib and initial height under hook of 47.9m. MR Concrete originally envisaged the MRH 175 for a two-crane project in Dublin, Ireland, but adapted it to suit the higher project in Glasgow. It will work on site for 50 weeks and will reach a final height under hook of 72.9m, using only one reinforced mast tie.

“We were very impressed with the erection and the speed of the crane in service – it’s quick and efficient,” said Matthew Rodden, managing director of MR Conrete. “It performs well and does everything we want it to do, operating much quicker than some other luffers.”

Although based in Buncranna, Co. Donegal, Ireland, MR Concrete operates throughout the United Kingdom and Republic of Ireland, where job sites are becoming more confined.

“We believe the new Potain hydraulic luffing topless cranes will have a very bright future in our industry and are looking forward to seeing the strong return on investment the MRH 175 will deliver for MR Concrete,” Ledwith concludes.

About M.R. Concrete and M.R. Concrete Crane Hire

CONTACT

Cristelle Lacourt

Manitowoc

T +33 472 182 018

cristelle.lacourt@manitowoc.com

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image