Manitowoc announces largest Potain luffing jib crane at bauma 2025

- The 64 t maximum capacity of the new MR 819 is twice that of the existing Potain MR 608B and MR 618 luffing jib tower cranes.

- The 70 m jib can be raised to create an out-of-service radius of just 16 m, making the crane ideal for congested jobsites.

- A powerful new winch, Potain CONNECT™, and Ultra View cab also feature.

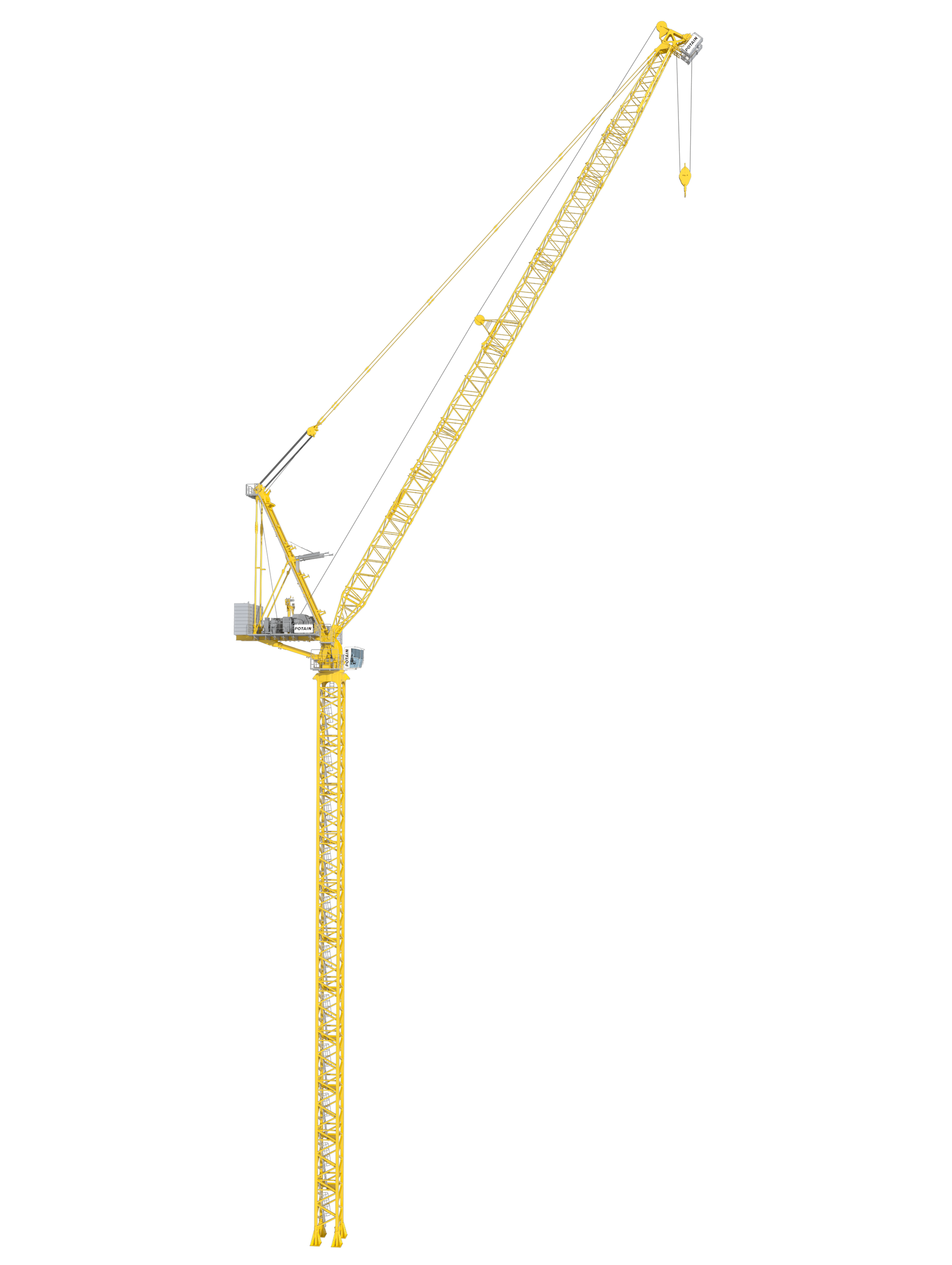

Manitowoc used bauma 2025 to reveal details of its largest Potain luffing jib crane for the European and North American markets. The MR 819 has up to 70 m of jib available and a maximum capacity of 64 t – double that of the current largest Potain luffing jib tower cranes, the 32 t capacity MR 608B and MR 618. Manitowoc’s Voice of the Customer (VOC) program was crucial to developing the latest flagship model, which addresses the demand for large luffing jib tower cranes to handle heavy precast elements and support infrastructure projects such as bridges and nuclear power plants.

“We developed the Potain MR 819 to support our large rental and high-profile contractor customers,” said Thibaut Le Besnerais, VP of marketing and development for tower cranes at Manitowoc. “To develop the new crane, we drew heavily on the design of our latest luffer, the MR 309. This allowed us to engineer a crane with optimally sized components that offer the easiest transport and assembly.”

This new design delivers a very short out-of-service radius – from 18 m to 16 m depending on jib length – allowing for installation on sites where space is limited, or a high density of cranes is required. Using a dozen 5 m sections of Potain’s strong new 2.45 m, K 880 mast system, the crane can be erected at a freestanding height of 65.6 m with jib configurations up to 50 m, or it can be configured at a 60.6 m height, using 11 mast sections plus the full nine sections of jib. When anchored to a building, it needs just five anchoring frames to reach 210 m with a 65 m jib (for a C25 wind profile).

When rigged with three-fall reeving and a 55 m jib, the MR 819’s 64 t maximum capacity can be lifted out to 17 m radius and up to 10.8 t can be lifted at the jib end. With two-fall reeving and a 65 m jib, it can lift 42 t out to 21 m and 7.4 t at maximum radius.

Supporting these loads required the development of a new, flexible, and precise hoisting winch, the 270 LVF 213 Optima. With 838 m of rope, the high winding capacity of its 200 kW motor can produce line speeds ranging from 183 m/min in single-fall reeving to 61 m/min in three-fall reeving. The 110 kW-rated 150 VVF 90 luffing hoist can raise the jib from 15° to 87° in just 2 min 20 sec. In addition, the Potain Power Control is included, which reduces the hoists’ energy demands for greater efficiency during less time-critical tasks. This is included with all Potain tower cranes with the manufacturer’s Crane Control System (CCS).

From the comfort of the Ultra View cab, the operator can enjoy a smooth and customizable driving experience, with fast and easy calibration made possible through CCS, Manitowoc’s industry-leading control system. And, of course, the MR 819 comes with the advanced POTAIN Connect™ telematics platform, to deliver a world of valuable data for fleet management, maintenance and troubleshooting.

CONTACT

Dominique Leullier

Marketing Director, Europe

Manitowoc

+33 4 72 18 21 60

dominique.leullier@manitowoc.com

Features

Crane Control System (CCS)

Manitowoc Crane Control System (CCS) – Offers a user-friendly interface, full graphic display, ergonomic controls, a jog dial for easier navigation and data input, and parts commonality across Grove, Manitowoc and Potain product lines enhancing operator familiarization and serviceability.

POTAIN

Top-Slewing Cranes

Top-Slewing cranes are the large construction sites most strategic equipment for productivity. Whether on large infrastructure, high rise jobsites, crowded urban areas or wide open sites, they make it possible to hoist and distribute loads high and far. The Potain brand is a global leader with its multiple ranges of topless cranes, luffing jib cranes and large hammerhead cranes that can also be customized to match special applications.